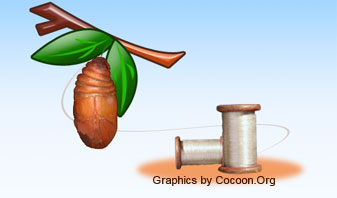

How Silk is made from Cocoons

Today the silk industry is worth a lot of money. It is actually worth anywhere between $200 and $500 million aeach year. This is because there is such great demand for items that are made from silk. Usually the species Bombyx mori is cultivated and raised under controlled conditions. There are various stages to this process. They include:

Today the silk industry is worth a lot of money. It is actually worth anywhere between $200 and $500 million aeach year. This is because there is such great demand for items that are made from silk. Usually the species Bombyx mori is cultivated and raised under controlled conditions. There are various stages to this process. They include:

• When the silk worm forms a covering around itself by secreting a protein through its head, this is called the cocoon stage. This is the most desirable stage for the silk producers. It is at this time that the cocoons are delivered to the factory by the farmer. These factories are called filature operations.

• Once the cocoons reach the filature operations they are sorted by color, size, shape and texture. They usually range from white and yellow to grayish.

• After the cocoons have been sorted, they have to be boiled in water, while they are still intact, for 5 minutes while they are being turned gently. They are then taken out of the water and a dissecting needle is used to start picking up the strands. Once a single strand is found that will come off easily it has to be wound around a pencil. This is how the cocoon is loosened so that it can be unwound in 1 continuous thread, which are collected into skeins. The process is called “reeling.”

• Since the thread is too fine for commercial use, between 3 and 10 strands then have to be reeled together to produce the desired diameter of raw silk. This is known as “reeled silk.” It will take 3,000 cocoons to make just 1 pound of this type of silk.

This silk must then be reeled into skeens and packed into small bundles called books. These are then shipped to silk mills around the world.

Bee Cocoons

What is a Cocoon

Cocoons in the winter time

How long Cocoon Last?

Silk Made From Cocoon

Silkworm Cocoon

Orgin of word Cocoon

The Surprises in Cocoons

Types of Insects in Cocoon

Butterfly or Moth Cocoon

Making of Cocoons

Ant – Cocoon Connection

From Cocoon to Adult: Role of Hormones

Cocoon that resembles a Bag

Cocoon Architecture

Mud Cocoons

Interesting Cocoons

Cocoon Food

Glochidium Cocoon

Sleeping Bag Cocoon

Cremaster, Nature’s Velcro

Frog Cocoon

Earthworm Cocoonv

Cocoon Rattles

Mites And Bee cocoon

Say No to Silk

Cocoon Inside Cocoon

Sensing From Inside Cocoon

Cocoon That Resembles Rabbit droppings

Hammock Shaped Cocoon

Chipwood Cocoon

Slime Cocoon

Cocoon For Eggs